Tuck Top Boxes

Explore our premium tuck top boxes, crafted to meet all your packaging needs with customization options in size, shape, and material.

Customizable Sizes for Every Need

Our tuck top boxes come in a variety of sizes, making them suitable for a wide range of products. Whether you need small boxes for delicate items or larger boxes for bulk packaging, we’ve got you covered. Our customization options ensure that you can choose the perfect dimensions for your products. This flexibility not only enhances the presentation but also optimises storage and shipping efficiency. Elevate your packaging game with our tailored sizing solutions!

Why Choose Blue Box Packaging?

FREE DESIGN SUPPORT

FAST TURNAROUND

CUSTOM SIZE & STYLE

WHOLESALE PRICING

NO MINIMUM

FREE SHIPPING

- Get Started

With just a few Steps, design your own boxes!

Get Free Quote

Get a free quote on any packaging project instantly, no matter how complex it is.

Material Selection

We suggest the perfect packaging material for your box once you select the box style.

Artwork Preparation

Share your artwork & design; if not, we will design it based on your suggestions.

Start Production

Once your artwork is approved, we'll begin production. We will support you at every step.

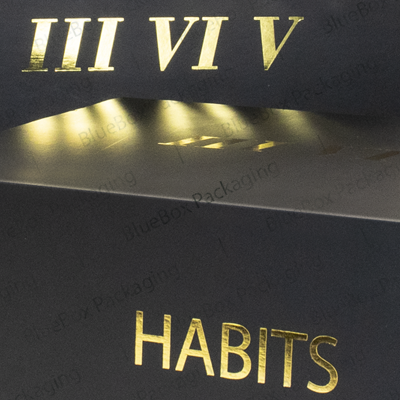

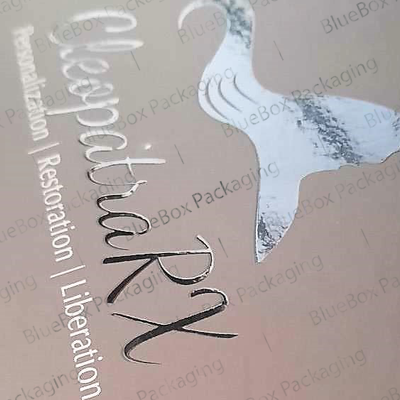

Eye-Catching Printing Options

Eco-Friendly Choices for Sustainable Packaging

In today’s world, sustainability matters more than ever. Our tuck top boxes can be made from recyclable and biodegradable materials, allowing you to reduce your environmental footprint. By choosing eco-friendly packaging solutions, you show your commitment to sustainability while still maintaining high quality and functionality. Our team is here to guide you in selecting the best eco-conscious options that align with your brand values, making it easier for you to appeal to environmentally aware consumers.

Wholesale Rates for Bulk Orders

Materials & Add-Ons

Frequently Asked Questions

-

Can I order a sample before placing a bulk order?

Yes, we encourage you to request a sample to assess the quality and design of our tuck top boxes. This way, you can ensure they meet your expectations before making a larger commitment.

-

Can I customise the size and shape of tuck top boxes?

Absolutely! We offer customisable sizes and shapes to suit your specific packaging needs. Whether you need standard sizes or unique shapes, we can accommodate your requirements.

-

What materials are available for tuck top boxes?

Our tuck top boxes can be made from a variety of materials, including cardboard, kraft paper, and eco-friendly options. You can choose the material that best fits your product and branding.

-

Are your tuck top boxes eco-friendly?

Yes! We offer eco-friendly packaging solutions made from recyclable and biodegradable materials. You can choose sustainable options that align with your brand's values and appeal to environmentally conscious consumers.

-

What are your wholesale rates?

We provide competitive wholesale rates for all our tuck top boxes. Pricing varies based on order size and customization options. Contact us for a quote tailored to your needs.

REQUEST CALLBACK

Let us know when we should reach out to discuss your packaging needs.

Fill out the form below and we will call you within 24 hours.

NEED SOME ADVISE? GET US ON

© 2023 www.blueboxpackaging.com.au. All rights reserved.